Fused Silica Ceramic Molds

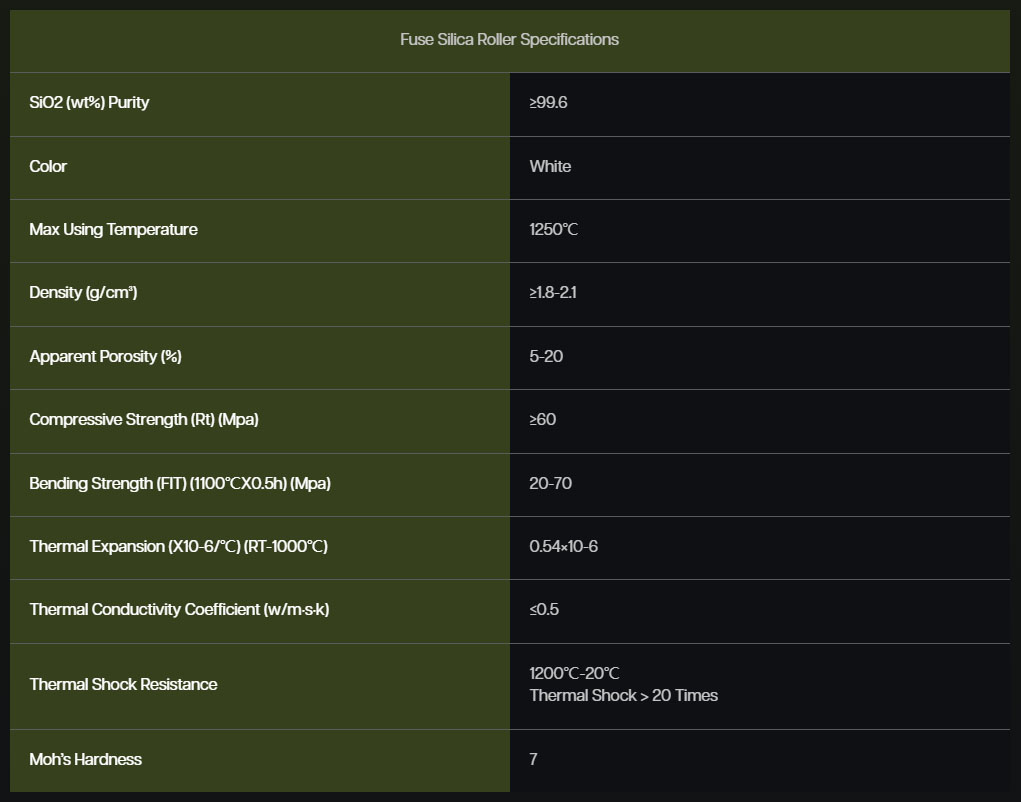

✦ Excellent High Temperature Resistance, Melting Point Up To 1800°C, Low Thermal Expansion Coefficient, Excellent Thermal Stability

✦ Excellent Mechanical Strength: High Compressive Strength, Strong Bending Strength, Good Wear Resistance

✦ Excellent Thermal Shock Resistance: Good Thermal Shock Resistance, Not Easy To Crack, Greatly Extending The Service Life

✦ Strong Chemical Stability, Strong Corrosion Resistance, Excellent Chemical Stability, Strong Resistance To Acid And Alkali Erosion

✦ Precision Molding Capability: High Precision, Dan dada, Good Dimensional Accuracy

♦ Ayika ore ati idoti-free: ko si ipalara oludoti, alawọ ewe ayika ore, ilana iṣelọpọ mimọ

Aworan ọja

Ijẹrisi ọja

-

Isapejuwe

-

Alaye

-

FA

Fused silica molds are a must-have for industries requiring precision and durability in their production processes. Their ability to withstand extremely high temperatures without deformation ensures the reliable replication of intricate details, crucial for maintaining high standards of quality. The low thermal expansion of fused silica minimizes the risk of cracking, preserving mold integrity even under rapid temperature changes. Additionally, their exceptional chemical resistance protects both the mold and the cast material from contamination, ensuring product purity.

Fused silica ceramic molds are at the forefront of advanced manufacturing and precision casting technologies. Composed of high-purity silicon dioxide, these molds are engineered to meet the stringent demands of industries where accuracy, stability, and superior material properties are paramount. Fused silica ceramic molds are widely used in applications requiring exact replicas of intricate designs, thanks to their exceptional thermal and chemical stability.

Applications of Fused Silica Ceramic Molds

Investment Casting: These molds are extensively used in investment casting for producing detailed and complex components, especially in the aerospace, ọkọra, and jewelry industries.

Ẹrọ pipe: Fused silica ceramic molds are critical in manufacturing high-precision parts where dimensional accuracy is crucial, such as in the production of turbine blades and medical devices.

Glass Molding: The optical clarity and thermal properties of fused silica make it an excellent choice for glass molding applications, including lenses and optical components.

Metal Casting: Suitable for casting various metals, including superalloys and titanium, fused silica molds ensure high-quality and defect-free components.

Prototyping and R&D: These molds are also valuable in research and development for prototyping new designs and testing material properties

Fused silica molds are extensively employed across various industries for precision molding and casting applications. Engineered to endure high temperatures, these molds ensure the accurate replication of intricate details in molded or cast objects. Their robustness and precision make them indispensable in sectors such as glass manufacturing, jewelry making, and metal casting.

Kí nìdí Trust Kamrollers

Kamroller is a leader in the development and supply of fused silica ceramic molds, providing products that meet the highest standards of quality and performance. Here’s why Kamroller is the preferred choice for your precision casting needs:

1.Imoye ati Innovation: With decades of experience in the field, Kamroller leverages cutting-edge technology and innovative processes to deliver superior products.

2.Didara ìdánilójú: Each fused silica ceramic mold undergoes stringent quality control procedures to ensure it meets the most demanding industry standards.

3. Onibara-Centric Ona: Kamroller places a strong emphasis on customer satisfaction, offering tailored solutions and expert technical support to meet specific requirements.

Features of Fused Silica Ceramic Molds

1.Smooth Surface Finish: The smooth surface of fused silica ceramic molds contributes to a superior surface finish on cast parts, reducing the need for post-processing.

2.Excellent Mechanical Strength: Fused silica molds possess excellent mechanical strength, which allows them to withstand significant physical stress during the casting process.

3.Dimensional Accuracy: The precision manufacturing of fused silica molds ensures tight dimensional tolerances, which is critical for producing parts that require exact specifications

4.Resistance to Thermal Shock: Fused silica’s ability to handle rapid temperature changes without cracking or breaking is a major advantage.

5.Minimal Outgassing: Fused silica molds exhibit minimal outgassing, making them suitable for use in vacuum environments or in processes where the release of gases could contaminate the product.

What are Fused Silica Ceramic Molds?

-Fused Silica Ceramic Molds are a kind of advanced ceramic mold material, usually used for casting metal products such as high-temperature alloys. This ceramic mold is made of silicon oxide and other additives, and has the characteristics of high heat resistance, corrosion resistance and high purity.

Advantages of Fused Silica Ceramic Molds

- Iduroṣinṣin iwọn otutu: Able to withstand extremely high temperature casting process without deformation or cracking. - High surface flatness: Able to produce metal products with smooth surface. -Good pouring fluidity: Ensure that the metal material can fully fill the mold.

Application fields of Fused Silica Ceramic Molds

-Ofurufu: used to manufacture engine parts, guide systems and other high-temperature alloy products. -Medical equipment: used to produce high-precision medical equipment parts. -Other fields: such as automobile manufacturing, electronics industry, ati be be lo.

Fused Silica Ceramic Molds Certification

- ISO certification: ensure product quality meets international standards and improves market competitiveness. - Quality inspection: test the physical properties, chemical composition, ati be be lo. of ceramic molds. - Usage guide: provide correct use and maintenance methods to extend the life of the mold

Maintenance of Fused Silica Ceramic Molds

- Gentle cleaning: Clean the surface regularly with a mild detergent to avoid damage. - Avoid drastic temperature differences: Avoid rapid temperature increases or decreases for a long time, which may cause the mold to crack.

Fused Silica Ceramic Molds Manufacturers

- Provide high-quality Fused Silica Ceramic Molds products. - Ceramic molds of different specifications and shapes can be customized according to customer needs.

How are fused silica ceramic molds maintained

They require careful handling to avoid contamination and should be stored in a controlled environment to maintain their properties.

What are the benefits of using fused silica ceramic molds

These molds offer superior surface finish, dimensional stability, and resistance to thermal shock.

What are the applications of fused silica ceramic molds?

They are used in industries like aerospace, ọkọra, and electronics for casting complex shapes with high accuracy.