Yakasanganiswa Silica Ceramic Mold YeGirazi Bending

✦ Kudzivirira kwekushisa kwepamusoro: – Yakatanhamara yakakwirira tembiricha kuramba, yakakodzera kune yakakwirira tembiricha nharaunda panguva yekukotama girazi maitiro. – Yakachengeteka uye yakavimbika, hazvisi nyore kuremara kana kutyora, kuve nechokwadi kugadzikana kwemaitiro ekugadzira.

✦ Precision machining: – Kushandisa advanced machining tekinoroji kuve nechokwadi chakatsetseka mold pamusoro uye kugadzirisa iko kuumbwa kwegirazi, – Kupa akasiyana siyana uye saizi kuti isangane nekugadzirisa zvinodiwa zvezvigadzirwa zvegirazi zvakasiyana.

✦ Kupfeka uye kusagadzikana kwekuora: – Iyo mold zvinhu zvine yakanakisa kupfeka kuramba uye corrosion kuramba, iyo inogona kushandiswa yakagadzikana kwenguva yakareba uye kuderedza kutsiva mari.

✦ Zvinhu zvepamusoro-soro: – Yakagadzirwa neyemhando yepamusoro fused quartz ceramic zvinhu, kuve nechokwadi chepamusoro kutsetseka uye kujeka kwegirazi rakaumbwa.

✦ Yakanyanya kugadzirwa: – Tsigira vatengi’ personalized customization inoda uye inopa yakagadziridzwa mold yekugadzira masevhisi zvinoenderana neakananga kugadzirisa zvinodiwa.

✦ Kuvimbika:- Mushure mehutano hwakasimba hwekutonga uye kuongororwa, chigadzirwa chemhando chakavimbika uye kushanda kwakagadzikana kunovimbiswa zvakanyanya.

Chigadzirwa chifananidzo

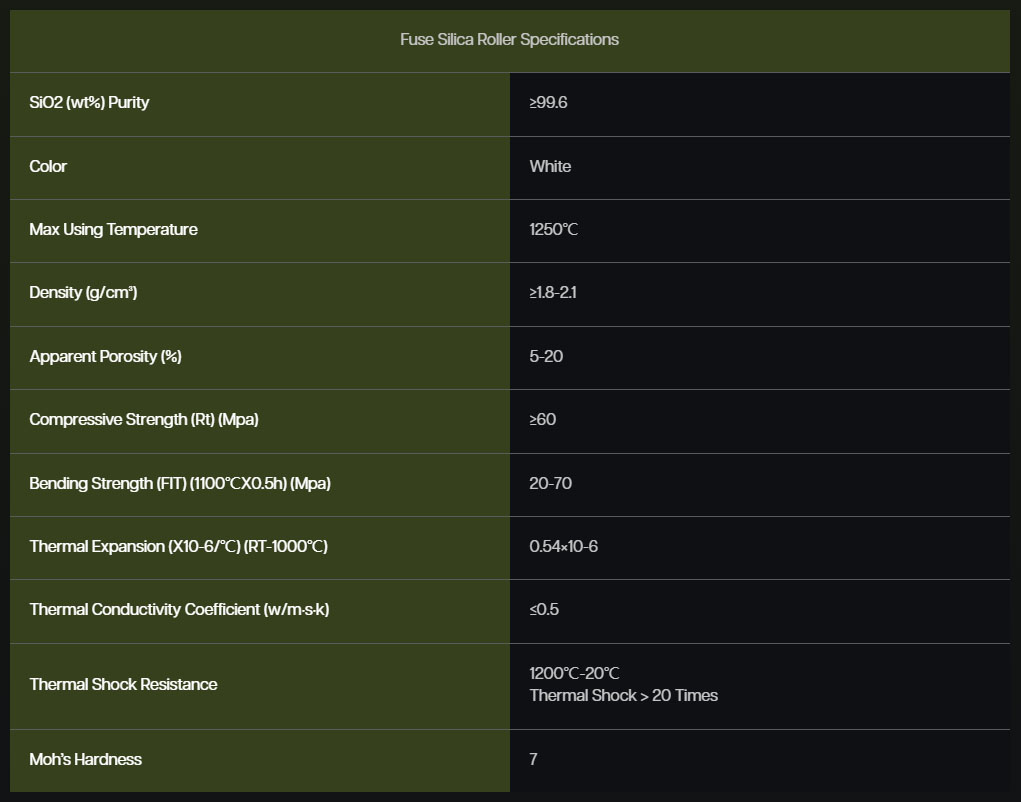

Chitupa chechigadzirwa

-

Tsanangudzo

-

Kutaurwa

-

Fqa

Iyo Fused Silica Ceramic Mold yakagadzirirwa kutsungirira kupisa kwakanyanya. Izvi zvinoita kuti zvive zvakanaka pakugadzira magirazi, metal casting, kilns, zviroto, uye mamwe maitiro ekupisa kwepamusoro. Kuumbwa kwayo kwakasiyana kunovimbisa kuwedzera kudiki kwekupisa, kudzivirira kutsemuka kana kukanganisa, kunyange pasi pekukurumidza kuchinja kwekushisa.

Iine dense uye isina-porous chimiro, iyo Fused Silica Ceramic Brick inoratidza kuramba kunoshamisa kwekuvhunduka kwekupisa, kemikari ngura, uye abrasion. Izvi zvinovimbisa hupenyu hwesevhisi hurefu uye kuita kunoenderana, ukuwo uchideredza nguva yekudzikira uye mari yekugadzirisa. Iyo Brick yakatsetseka uye yakapfava nzvimbo inopa yakanakisa kuonana uye kugadzikana kana ichishandiswa senge lining kana tsigiro zvinhu.

Iyo Fused Silica Ceramic Mold yeGlass Bending inomiririra iyo yepamusoro yeinjiniya chaiyo, Yakagadzirwa zvine hungwaru kuti isangane nezvinodiwa chaizvo zvekugadzira magirazi maitiro. Yakagadzirwa neinocheka-kumucheto tekinoroji uye hunyanzvi, iyi yakasarudzika mold inoita basa rakakosha mukugadzira uye kupeta girazi nekurongeka kusingaenzaniswi uye kuvimbika.. Yakagadzirwa kuti imirire tembiricha yakanyanyisa uye kupisa bhasikoro kunowanikwa mumagirazi ekubhenda maapplication, iyo Fused Silica Ceramic Mold inova nechokwadi chekuenderana uye chaiyo mhedzisiro, zvichiita kuti chive chishandiso chakakosha mukugadzira zvigadzirwa zvemhando yepamusoro zvegirazi.

Zvishandiso zveFused Silica Ceramic Mold yeGirazi Kubhenda

Iyo Fused Silica Ceramic Mold yeGirazi Kubhenda inowana yakafara kushanda muindasitiri yegirazi, kusanganisira:

Girazi reArchitectural: Inoshandiswa mukugadzira magirazi akakomberedzwa uye akabhenda mapaneru ekuvakwa kwekushandisa, semahwindo, mikova, uye skylights

Girazi remotokari: Anoshandiswa mukugadzira macurved windshields, Side Windows, uye mahwindo ekumashure emotokari, kuve nechokwadi chekukotama uye kuumbwa kwekwakaringana kukwana uye kushanda.

Girazi remotokari: Anoshandiswa mukugadzira macurved windshields, Side Windows, uye mahwindo ekumashure emotokari, kuve nechokwadi chekukotama uye kuumbwa kwekwakaringana kukwana uye kushanda.

Girazi Furniture: Inoshandiswa kupeta uye kugadzira magirazi emidziyo anoshandiswa mukugadzira fenicha, zvakadai segirazi tabletop, masherufu, uye kuratidza makesi.

Glassware uye Tableware: Yakakosha mukugadzirwa kwecurved glassware uye tableware zvinhu, kusanganisira mbiya, vases, uye kugovera ndiro, zvekushandisa zvese zvekutengesa uye zvekugara.

Nei Traving Kampers

Kamroller akawana mukurumbira semutungamiri akavimbika muinjiniya chaiyo, nekuzvipira kuendesa zvigadzirwa zvemhando yepamusoro uye sevhisi yakasarudzika yevatengi. Ichi ndicho chikonzero iwe uchigona kuvimba neKamroller kune yako Fused Silica Ceramic Mold yeGlass Bending zvinodiwa.:

Neruzivo rwakakura mukugadzira girazi maitiro, Kamroller ine ruzivo uye hunyanzvi hwekuburitsa ma molds emhando yepamusoro akarongedzerwa kune zvakasarudzika zvinodiwa nemutengi wega wega..

Kamrollers inopa mhinduro dzakagadzirirwa kusangana nezvinodiwa nevatengi, inopa sevhisi yakasarudzika uye nhungamiro yehunyanzvi mukati mekuita.

Yese Silica Ceramic Mold inopinda yakaomesesa yemhando yekudzora macheki kuti ive nechokwadi, kuvimbika, uye kuita, kuomerera kune yepamusoro indasitiri zviyero.

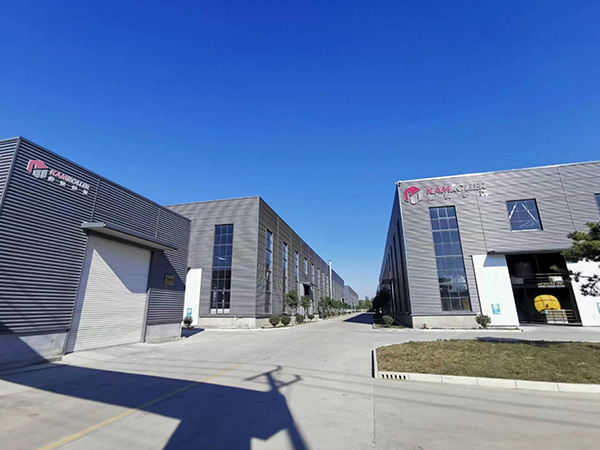

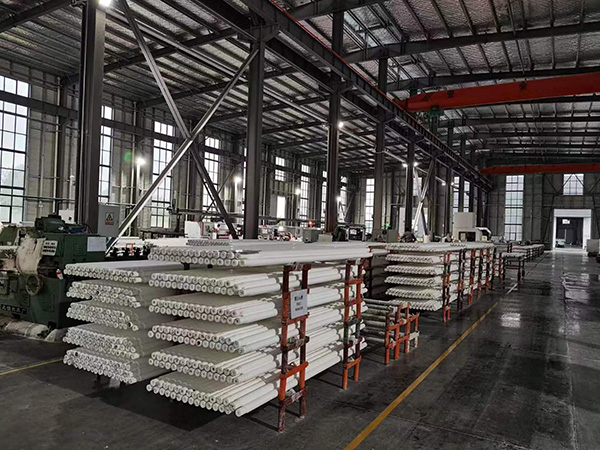

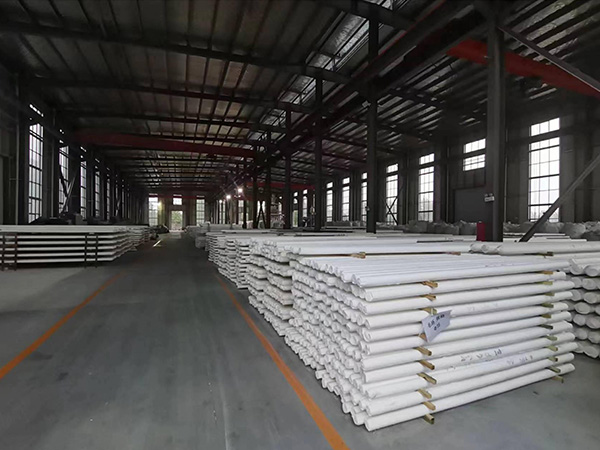

Mufananidzo Wedu Wefekitari:

Packing Detail:

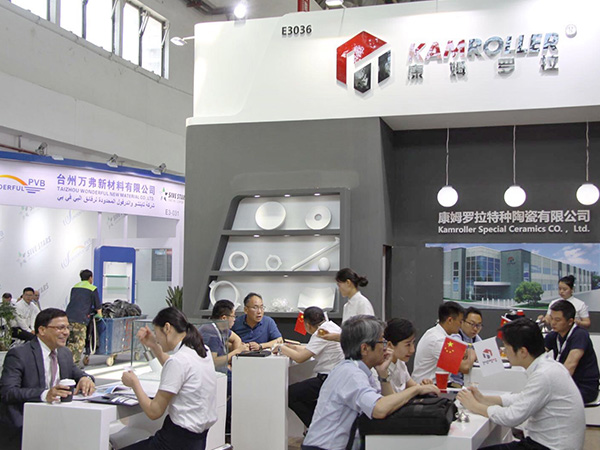

Kampers PaThe Exhibition:

ISO Chitupa:

Fused silica ceramic molds chinhu chakakosha muindasitiri yekubhenda girazi, kupa kupisa kwepamusoro kuramba, kuwedzera kwekushisa kwepasi, uye kusimba kwakanakisa. Kugadzirisa kwakakodzera uye kubata kwakakosha kuti uwedzere hupenyu hwavo nekuita. Yezvikumbiro zvehunyanzvi, zviumbwa zvakagadzirirwa zvinogona kugadzirwa kuti zvienderane nezvinodiwa chaizvo.

Chii chinonzi fused silica ceramic mold?

A fused silica ceramic mold imhando ye mold yakagadzirwa kubva ku high-purity silica (Sio2) iyo yakanyungudutswa nekutonhodzwa kuti iite gobvu, isina-crystalline chimiro. Aya ma mold anoshandiswa mugirazi rekukotama maitiro kuumba uye kugadzira girazi mune chaiyo contours uye magadzirirwo.

Ndeapi mabhenefiti ekushandisa akasanganiswa silica ceramic molds yekukotama girazi?

Kupisa kwakanyanya: Yakasanganiswa silica ceramic molds inogona kumira zvakanyanya kudziya tembiricha isina kukanganiswa kana kutyora. Low Thermal Kuwedzera: Vane coefficient yakaderera zvikuru yekuwedzera kwekupisa, zvinoreva kuti vanochengetedza chimiro chavo uye saizi kunyangwe painenge paine tembiricha yakanyanya. Yakanakisa Thermal Shock Resistance: Aya ma mold anogona kutsungirira nekukurumidza kuchinja kwekushisa pasina kutsemuka kana kukuvadza. Smooth Surface: Inopa kupedzisa kwemhando yepamusoro pane zvigadzirwa zvegirazi. Kugara kwenguva refu: Iyo yakasimba uye inogona kushandiswazve kakawanda.

Inoitwa sei yakasanganiswa silica ceramic molds?

Maitiro ekugadzira anowanzo sanganisira kunyunguduka yakakwirira-kuchena silica poda uye wozoitonhodza nekukurumidza kuti iite yakasimba chimiro.. Iyi nzira inogona kuitwa nenzira dzakasiyana-siyana, sekuti slip casting, kudzvanya, kana kugadzira, kuti uwane chimiro chaunoda mold.

Ndeapi marudzi ezvigadzirwa zvegirazi zvinogona kugadzirwa uchishandisa zviumbwa izvi?

Fused silica ceramic molds inoshandiswa kugadzira akawanda egirazi zvigadzirwa, kusanganisira girazi remotokari (windshields, Side Windows), girazi rekuvaka (curved glass panels), uye specialty glass zvinhu (Optical Lenses, girazi rekushongedza).

Iwe unochengetedza sei uye unotarisira yakasanganiswa silica ceramic mold?

Nguva Dzose Kuchenesa: Chengetedza mold yakachena kubva kune chero magirazi akasara kana zvinosvibisa. Kuchengeta Kwakakodzera: Chengetedza molds mune yakaoma, nzvimbo inotonhorera kudzivirira kunyura kwemwando uye kuvhunduka kwekushisa. Bata Nekungwarira: Dzivisa kudonhedza kana kurova molds kudzivirira kutsemuka uye machipisi. Nguva yekuongorora: Gara uchiongorora ma mold pane chero zviratidzo zvekusakara kana kukuvadzwa uye kugadzirisa kana kutsiva iwo sezvinodiwa.

Inogona kusanganiswa silica ceramic molds kugadzirwa?

Ehe, yakasanganiswa silica ceramic molds inogona kugadzirwa kuti isangane nezvinodiwa zvechimiro, saizi, uye kugadzirwa kwepamusoro. Vagadziri vanogona kushanda nevatengi kugadzira uye kugadzira mold inoenderana neyavo yakasarudzika girazi inokotama zvavanoda.

Ndeapi maindasitiri anowanzo shandisa fused silica ceramic molds?

Automotive Industry: Zvekuumba magirazi emotokari zvikamu. Indasitiri yekuvaka: Zvekukotama zvekuvaka girazi zvinhu. Optical Industry: Kune chaiyo girazi lenzi uye optical components. Inoshongedza Girazi Indasitiri: Nekugadzira zvidimbu zvegirazi zveunyanzvi uye zvekushongedza.

Ndeapi akajairwa zvipimo zve fused silica ceramic molds?

Mutengo: Fused silica ceramic molds can be more expensive compared to other types of molds due to the material's high purity and manufacturing process. Fragility: Kunyange zvazvo dzichigara pasi pekushisa kwepamusoro, anogona kunge asina kusimba uye anogona kutyoka kana akabatwa zvisina kunaka.

Iwe unosarudza sei iyo yakakodzera fused silica ceramic mold yechishandiso chako?

Chimbofunga zvinhu zvakadai serudzi rwegirazi riri kubhenda, zvinodiwa tembiricha, kuoma kwechimiro, uye huwandu hunotarisirwa hwekugadzira. Kubvunzurudza nemugadziri anonyanya kusanganisa silica ceramic molds kunogona kubatsira kuve nechokwadi chekuti unosarudza mold yakakodzera pane zvaunoda..

Pane dzimwe nzira dzekusanganisa silica ceramic molds?

Ehe, zvimwe zvinosanganisira magirafu molds, metal molds, uye mamwe marudzi e ceramic molds. Chinyorwa chimwe nechimwe chine gadziriro dzayo dzezvakanakira uye ganhuriro, uye sarudzo inoenderana nezvinodiwa chaizvo zvegirazi rekukotama maitiro.