Btieti tas-Silika Mdewba

✦ Excellent Heat Resistance: Made Of High-Purity Fused Quartz Material, It Can Withstand High Temperature Furnace Environment.

✦ Excellent Chemical Stability: Anti-Corrosion Properties, Suitable For Various Chemical Reagents And Solvents

✦ Precise Processing And Dimensional Stability: Precise Manufacturing Process, Precise And Stable Dimensions, Suitable For Precision Instrument Parts

✦High Transparency And Low Ripple: Proprjetajiet Ottiċi Eċċellenti, Adattat għal Sistemi Laser U Komponenti tas-Sistema Ottika

✦ Koeffiċjent ta 'Espansjoni Termali Ultra-Baxxa: Prestazzjoni ta 'Espansjoni Termali estremament Baxxa, Stabbiltà Għolja, Adattat għal Ġestjoni ta 'Kontroll Termali ta' Preċiżjoni Għolja

♦ Favur l-ambjent u mingħajr tniġġis: ebda sustanzi ta 'ħsara, materjali ħodor favur l-ambjent, proċess ta 'produzzjoni nadif

Immaġni tal-Prodott

Ċertifikazzjoni tal-Btieli tas-Silika Fused

ISO9001, ċertifikazzjoni CE,Ċertifikazzjoni ambjentali RoHS

Speċifikazzjonijiet tal-prodott: Dijametru intern: 20-150 mm, Tul: 50-500 mm, Ħxuna tal-ħajt: 2-10 mm

-

DESKRIZZJONI

-

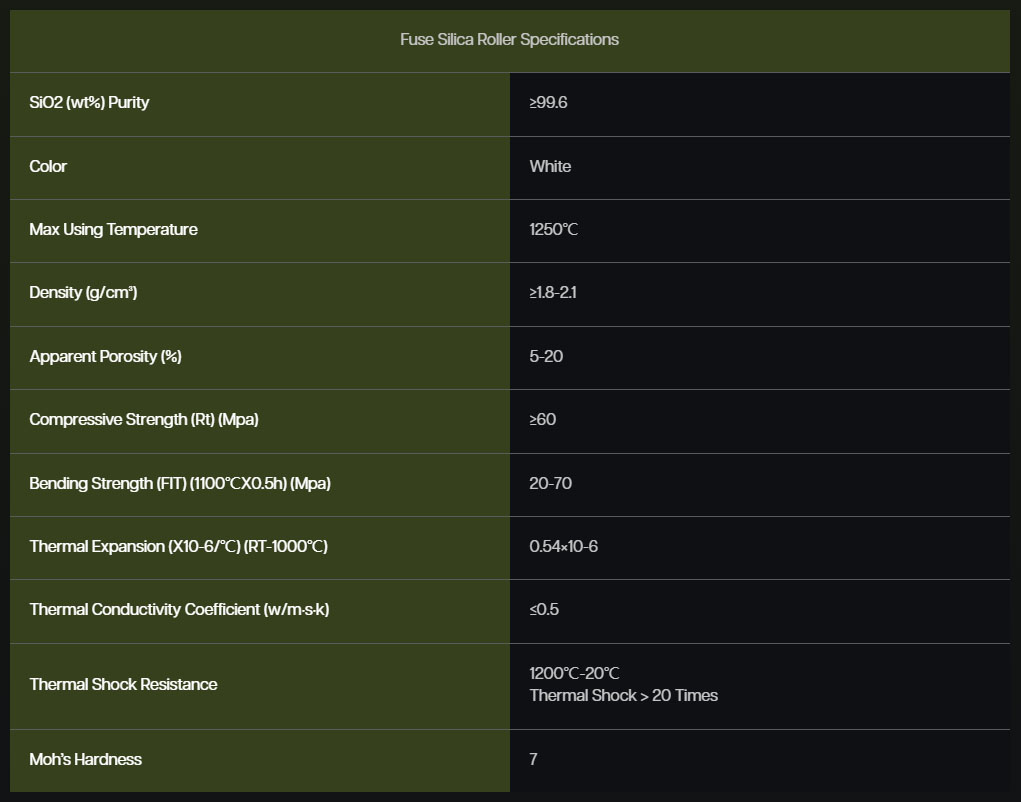

SPEĊIFIKAZZJONI

-

FQA

Btieti tas-Silika Mdewba, also known as Fused Silica Rollers, are high-purity cylindrical components made from fused silica, primarily composed of silicon dioxide (SiO2). These barrels are engineered to offer exceptional performance in various industrial applications, particularly those requiring high-temperature resistance, chemical stability, and mechanical strength. With a purity level of ≥99.6%, Fused Barrels are ideal for processes that demand minimal contamination and superior material integrity.

Including fused silica plates, fused silica crucibles, material bowls for glass furnaces, ends, punch, stirring slurry, uniform cylinders, etc., widely used in vertical glass drawing pipelines and glass-ceramic production lines, also according to customer drawings products in other complex shapes. Due to quartz ceramics’ excellent thermal shock resistance, preheating the hot state is unnecessary; it is resistant to glass corrosion, has no pollution to the glass liquid, has high strength, and has a long service life.

Features of Fused Silica Barrel

✦ High Purity: Made from 99.99% pure silicon dioxide, fused silica barrels exhibit superior purity, ensuring no contamination in sensitive processes.

✦ Thermal Stability: These barrels can withstand extreme temperatures without deforming or degrading, making them ideal for high-temperature applications.

✦ Thermal Stability: These barrels can withstand extreme temperatures without deforming or degrading, making them ideal for high-temperature applications.Chemical Resistance: Fused silica is highly resistant to acids, bases, and other aggressive chemicals, ensuring longevity and reliability in harsh environments.

✦ Low Thermal Expansion: The minimal thermal expansion of fused silica prevents cracking and maintains structural integrity even under rapid temperature changes.

✦ Optical Clarity: Fused silica’s optical clarity allows for precise monitoring and measurement, crucial in applications like spectroscopy and photonics.

Applications of Fused Silica Barrels

Semiconductor Manufacturing: Used in the fabrication of semiconductor devices, fused barrels provide the high purity and thermal stability necessary for precision etching and deposition processes.

Aerospace and Defense: In these sectors, the exceptional thermal properties and durability of silica are vital for components exposed to extreme conditions.

Scientific Research: Laboratories use silica barrels in experiments that require high-temperature environments and resistance to chemical reactions.

Medical Devices: The biocompatibility and non-reactive nature of fused silica make it suitable for use in medical and dental instruments.

Optical Fiber Production: Fused silica barrels are integral in the manufacturing process of optical fibers, where their clarity and stability ensure high-quality output.

Our Fused Barrels are the perfect choice for industries that demand high performance, affidabbiltà, and durability. With their advanced material properties and precise engineering, they ensure optimal performance in the most challenging environments. Choose our Fused Silica Barrels for superior quality and unmatched performance.

Għaliex Trust Kamroller

Kamroller stands at the forefront of fused silica technology, committed to delivering products that meet the highest standards of quality and performance. Here’s why you can trust Kamroller for your fused silica barrel needs:

Expertise and Innovation: With decades of experience in materials science, Kamroller continually innovates to provide state-of-the-art solutions tailored to industry requirements.

Expertise and Innovation: With decades of experience in materials science, Kamroller continually innovates to provide state-of-the-art solutions tailored to industry requirements.

Customer Focus: Kamroller prioritizes customer satisfaction, offering personalized service and technical support to meet your specific needs.

Bħala materjal ewlieni fl-industrija tas-semikondutturi u l-qasam ottiku, btieti tal-kwarz imdewweb għandhom valur ta 'applikazzjoni importanti u prospetti ta' żvilupp. Billi tottimizza l-proċess tal-manifattura u ttejjeb il-kwalità tal-prodott, nistgħu nilħqu aħjar il-ħtiġijiet ta 'oqsma differenti u nippromwovu l-iżvilupp u l-innovazzjoni ta' industriji relatati.

X'inhuma Fused Silica Barrels

Btieti tas-Silika Mdewba: Materjal importanti użat fl-industrija tas-semikondutturi b'purità għolja u reżistenza eċċellenti tas-sħana

X'inhuma l-vantaġġi tal-btieti tas-silika mdewba?

- Stabbiltà ta 'temperatura għolja: Kapaċi jiflaħ temperaturi estremament għoljin mingħajr ma jdub jew jiddeforma - Inertezza kimika: Reżistenza tajba għall-korrużjoni għal varjetà ta 'kimiċi - Trasparenza ottika**: Għandu trasparenza ottika eċċellenti u huwa adattat għall-ipproċessar u l-iskoperta ottika. - Ipproċessar ta' preċiżjoni**: Jista 'jiġi pproċessat b'mod preċiż f'diversi forom biex jissodisfa bżonnijiet differenti.

X'inhuma l-oqsma ewlenin ta 'applikazzjoni tal-btieti tas-silika mdewba?

- Manifattura ta' semikondutturi**: użati biex jimmanifatturaw komponenti ewlenin ta 'tagħmir tal-proċess tas-semikondutturi bħal magni tal-litografija u tagħmir ta' depożizzjoni ta 'film irqiq. - Strumenti ottiċi**: addattat għall-manifattura ta’ lentijiet u komponenti ottiċi ta’ tagħmir ottiku bħal teleskopji u spettrometri. - Esperimenti kimiċi**: bħala kontenituri tal-ħażna għal reaġenti kimiċi, jifilħu temperaturi għoljin u sustanzi korrużivi.

X'inhu l-proċess ta 'manifattura ta' btieti tas-silika mdewba?

- Tidwib**: Tisħin ta 'materjal tas-silika ta' purità għolja għal stat imdewweb. - Molding**: Iffurmar tas-silika mdewba f'forma ta 'barmil bl-użu ta' moffa jew teknoloġija ta 'magni ta' preċiżjoni. - Ittemprar**: L-eliminazzjoni tal-istress intern billi tikkontrolla t-temperatura u l-ħin biex ittejjeb ir-reżistenza tas-sħana u l-istabbiltà tal-kanna tal-kwarz imdewweb.

X'inhuma l-problemi u s-soluzzjonijiet komuni ta 'btieti tal-kwarz imdewweb? .

- Xquq ta' xokk termali**: Xquq jidhru taħt bidliet rapidi fit-temperatura. - Soluzzjoni**: Ottimizza l-proċess ta 'ttemprar biex ittejjeb l-istabbiltà termali tal-kanna tal-kwarz imdewweb. - Erożjoni kimika**: Ħsara kkawżata minn sustanzi korrużivi bħal aċidi u alkali qawwija. - Soluzzjoni**: Ittejjeb il-kisi tal-wiċċ jew agħżel materjali b'reżistenza għall-korrużjoni aktar b'saħħitha. - Ineżattezza fil-forma**: Devjazzjoni tal-forma jew irregolarità li sseħħ matul il-proċess tal-manifattura. - Soluzzjoni**: Ottimizza l-proċess tal-manifattura, issaħħaħ il-kontroll tal-kwalità, u tiżgura l-eżattezza tal-prodott. - bżieżaq interni**: Gassijiet preżenti fil-materjal huma maqbuda fil-bittija, jaffettwaw il-ħajja tas-servizz u l-prestazzjoni tiegħu. - Soluzzjoni**: Ottimizza l-proċess ta 'purifikazzjoni tal-materjal, tnaqqas ir-residwi tal-gass, u ttejjeb il-kwalità tal-materjal.

X'inhu l-metodu ta 'manutenzjoni ta' barmil tal-kwarz imdewweb?

- Tindif regolari**: Uża aġent tat-tindif speċjali biex tnaddaf il-wiċċ biex tneħħi s-sediment u l-ħmieġ. - Evita ħabta**: Immaniġġja b'attenzjoni u evita ħabta ma 'oġġetti iebsa biex tevita grif jew ħsara fil-wiċċ. - Ħażna xierqa**: Evita espożizzjoni fit-tul għal temperatura għolja jew ambjent umdu, u agħżel post ta 'ħażna niexef u ventilat. - Spezzjoni regolari**: Iċċekkja regolarment il-wiċċ għal xquq jew ħsara, u ssewwiha jew ibdelha fil-ħin