Casgenni Silica Ymdoddedig

✦ Excellent Heat Resistance: Made Of High-Purity Fused Quartz Material, It Can Withstand High Temperature Furnace Environment.

✦ Excellent Chemical Stability: Anti-Corrosion Properties, Suitable For Various Chemical Reagents And Solvents

✦ Precise Processing And Dimensional Stability: Precise Manufacturing Process, Precise And Stable Dimensions, Suitable For Precision Instrument Parts

✦High Transparency And Low Ripple: Priodweddau Optegol Ardderchog, Yn addas ar gyfer systemau laser a chydrannau system optegol

✦ Cyfernod Ehangu Thermol Ultra-Isel: Perfformiad Ehangu Thermol Eithriadol o Isel, Sefydlogrwydd Uchel, Yn addas ar gyfer rheoli rheolaeth thermol manwl uchel

♦ Yn gyfeillgar i'r amgylchedd ac yn rhydd o lygredd: dim sylweddau niweidiol, deunyddiau gwyrdd sy'n gyfeillgar i'r amgylchedd, proses gynhyrchu lân

Delwedd Cynnyrch

Ardystiad Casgenni Silica Ymdoddedig

ISO9001, ardystiad CE,Ardystiad amgylcheddol RoHS

Manylebau cynnyrch: Diamedr mewnol: 20-150 mm, Hyd: 50-500 mm, Trwch wal: 2-10 mm

-

DISGRIFIAD

-

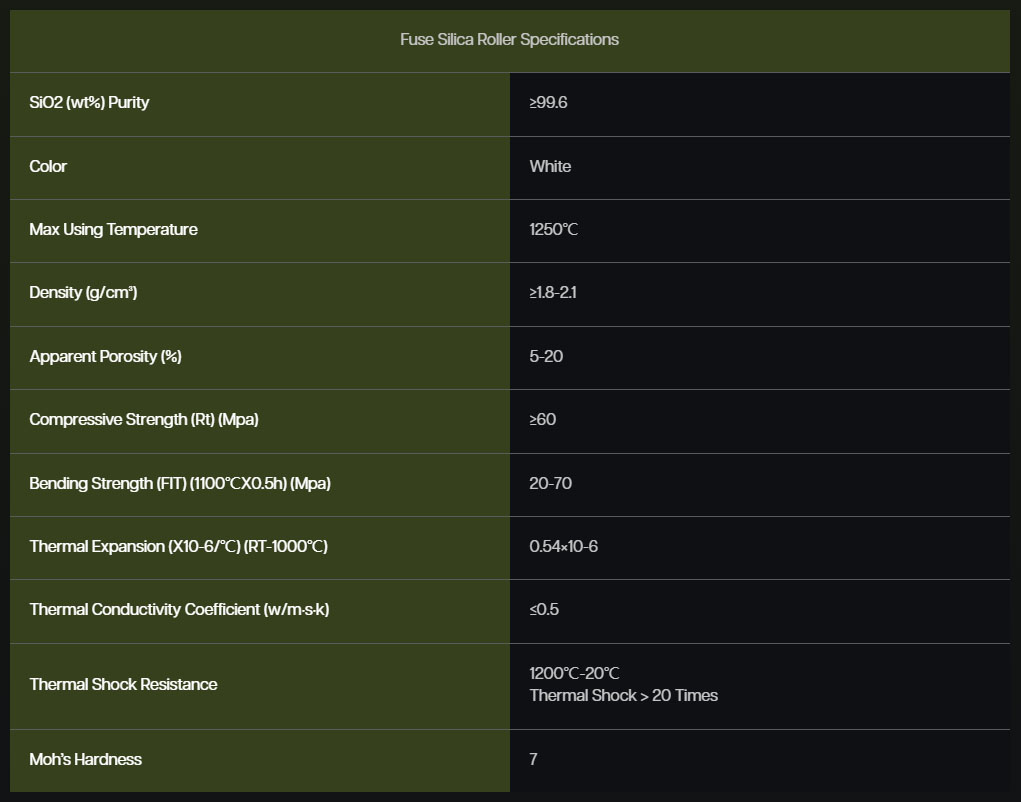

MANYLEB

-

FQA

Casgenni Silica Ymdoddedig, also known as Fused Silica Rollers, are high-purity cylindrical components made from fused silica, primarily composed of silicon dioxide (SiO2). These barrels are engineered to offer exceptional performance in various industrial applications, particularly those requiring high-temperature resistance, chemical stability, and mechanical strength. With a purity level of ≥99.6%, Fused Barrels are ideal for processes that demand minimal contamination and superior material integrity.

Including fused silica plates, fused silica crucibles, material bowls for glass furnaces, ends, punch, stirring slurry, uniform cylinders, etc., widely used in vertical glass drawing pipelines and glass-ceramic production lines, also according to customer drawings products in other complex shapes. Due to quartz ceramics’ excellent thermal shock resistance, preheating the hot state is unnecessary; it is resistant to glass corrosion, has no pollution to the glass liquid, has high strength, and has a long service life.

Features of Fused Silica Barrel

✦ High Purity: Made from 99.99% pure silicon dioxide, fused silica barrels exhibit superior purity, ensuring no contamination in sensitive processes.

✦ Thermal Stability: These barrels can withstand extreme temperatures without deforming or degrading, making them ideal for high-temperature applications.

✦ Thermal Stability: These barrels can withstand extreme temperatures without deforming or degrading, making them ideal for high-temperature applications.Chemical Resistance: Fused silica is highly resistant to acids, bases, and other aggressive chemicals, ensuring longevity and reliability in harsh environments.

✦ Low Thermal Expansion: The minimal thermal expansion of fused silica prevents cracking and maintains structural integrity even under rapid temperature changes.

✦ Optical Clarity: Fused silica’s optical clarity allows for precise monitoring and measurement, crucial in applications like spectroscopy and photonics.

Applications of Fused Silica Barrels

Gweithgynhyrchu Lled-ddargludyddion: Used in the fabrication of semiconductor devices, fused barrels provide the high purity and thermal stability necessary for precision etching and deposition processes.

Aerospace and Defense: In these sectors, the exceptional thermal properties and durability of silica are vital for components exposed to extreme conditions.

Scientific Research: Laboratories use silica barrels in experiments that require high-temperature environments and resistance to chemical reactions.

Medical Devices: The biocompatibility and non-reactive nature of fused silica make it suitable for use in medical and dental instruments.

Optical Fiber Production: Fused silica barrels are integral in the manufacturing process of optical fibers, where their clarity and stability ensure high-quality output.

Our Fused Barrels are the perfect choice for industries that demand high performance, dibynadwyedd, a gwydnwch. With their advanced material properties and precise engineering, they ensure optimal performance in the most challenging environments. Choose our Fused Silica Barrels for superior quality and unmatched performance.

Why Trust Kamroller

Kamroller stands at the forefront of fused silica technology, committed to delivering products that meet the highest standards of quality and performance. Here’s why you can trust Kamroller for your fused silica barrel needs:

Expertise and Innovation: With decades of experience in materials science, Kamroller continually innovates to provide state-of-the-art solutions tailored to industry requirements.

Expertise and Innovation: With decades of experience in materials science, Kamroller continually innovates to provide state-of-the-art solutions tailored to industry requirements.

Customer Focus: Kamroller prioritizes customer satisfaction, offering personalized service and technical support to meet your specific needs.

Fel deunydd allweddol yn y diwydiant lled-ddargludyddion a maes optegol, mae gan gasgenni cwarts ymdoddedig werth cymhwyso pwysig a rhagolygon datblygu. Trwy optimeiddio'r broses weithgynhyrchu a gwella ansawdd y cynnyrch, gallwn ddiwallu anghenion gwahanol feysydd yn well a hyrwyddo datblygiad ac arloesedd diwydiannau cysylltiedig.

Beth yw Casgenni Silica Ymdoddedig

Casgenni Silica Ymdoddedig: Deunydd pwysig a ddefnyddir yn y diwydiant lled-ddargludyddion gyda phurdeb uchel a gwrthsefyll gwres rhagorol

Beth yw manteision casgenni silica ymdoddedig?

- Sefydlogrwydd tymheredd uchel: Yn gallu gwrthsefyll tymereddau uchel iawn heb doddi nac anffurfio - Inertness cemegol: Gwrthiant cyrydiad da i amrywiaeth o gemegau - Tryloywder optegol**: Mae ganddo dryloywder optegol rhagorol ac mae'n addas ar gyfer prosesu a chanfod optegol. - Prosesu manwl gywir**: Gellir ei brosesu'n fanwl gywir i wahanol siapiau i ddiwallu gwahanol anghenion.

Beth yw prif feysydd cais casgenni silica ymdoddedig?

- Gweithgynhyrchu lled-ddargludyddion**: a ddefnyddir i gynhyrchu cydrannau allweddol o offer proses lled-ddargludyddion megis peiriannau lithograffeg ac offer dyddodiad ffilm tenau. - Offerynnau optegol**: addas ar gyfer gweithgynhyrchu lensys a chydrannau optegol offer optegol megis telesgopau a sbectromedrau. - Arbrofion cemegol**: fel cynwysyddion storio ar gyfer adweithyddion cemegol, maent yn gwrthsefyll tymereddau uchel a sylweddau cyrydol.

Beth yw'r broses weithgynhyrchu o gasgenni silica ymdoddedig?

- Yn toddi**: Cynhesu deunydd silica purdeb uchel i gyflwr tawdd. - Mowldio**: Mowldio'r silica tawdd i siâp casgen gan ddefnyddio llwydni neu dechnoleg peiriannu manwl. - Anelio**: Dileu straen mewnol trwy reoli tymheredd ac amser i wella ymwrthedd gwres a sefydlogrwydd y gasgen cwarts ymdoddedig.

Beth yw problemau ac atebion cyffredin casgenni cwarts ymdoddedig? .

- Craciau sioc thermol**: Mae craciau yn ymddangos o dan newidiadau tymheredd cyflym. - Ateb**: Optimeiddio'r broses anelio i wella sefydlogrwydd thermol y gasgen cwarts ymdoddedig. - Erydiad cemegol**: Difrod a achosir gan sylweddau cyrydol fel asidau cryf ac alcalïau. - Ateb**: Gwella'r cotio wyneb neu ddewis deunyddiau sydd ag ymwrthedd cyrydiad cryfach. - Anghywirdeb siâp**: Gwyriad siâp neu afreoleidd-dra sy'n digwydd yn ystod y broses weithgynhyrchu. - Ateb**: Optimeiddio'r broses weithgynhyrchu, cryfhau rheolaeth ansawdd, a sicrhau cywirdeb cynnyrch. - Swigod mewnol**: Mae nwyon sy'n bresennol yn y deunydd yn cael eu dal yn y gasgen, effeithio ar ei fywyd gwasanaeth a pherfformiad. - Ateb**: Optimeiddio'r broses puro deunyddiau, lleihau gweddillion nwy, a gwella ansawdd y deunydd.

Beth yw dull cynnal a chadw casgen cwarts ymdoddedig?

- Glanhau rheolaidd**: Defnyddiwch asiant glanhau arbennig i lanhau'r wyneb i gael gwared â gwaddod a baw. - Osgoi gwrthdrawiad**: Triniwch yn ofalus ac osgoi gwrthdaro â gwrthrychau caled i atal crafiadau arwyneb neu ddifrod. - Storfa briodol**: Osgoi amlygiad hirdymor i dymheredd uchel neu amgylchedd llaith, a dewis lleoliad storio sych ac awyru. - Archwiliad rheolaidd**: Gwiriwch yr wyneb yn rheolaidd am graciau neu ddifrod, a'i atgyweirio neu ei ddisodli mewn pryd