የተቀላቀለ ሲሊካ ሴራሚክ ሮለር

✦ High temperature stability: – Excellent high temperature resistance, suitable for high temperature working environment – Little effect of temperature changes, strong stability

✦ Excellent surface finish: – High surface flatness, conducive to the production of high-quality products – Not easy to produce scratches, improve production efficiency

✦ Low thermal expansion coefficient: – The thermal expansion and contraction have little effect, maintaining stable dimensions – Can reduce process errors caused by temperature changes

✦ Strong Chemical Stability, Strong Corrosion Resistance, Excellent Chemical Stability, Strong Resistance To Acid And Alkali Erosion

✦ Strong chemical stability: – Strong corrosion resistance, suitable for a variety of chemical environments – Good acid and alkali resistance, extending service life

♦ Good wear resistance: – Strong wear resistance and long service life – Reduce maintenance costs and improve equipment reliability

የምርት ምስል

የምርት የምስክር ወረቀት

-

መግለጫ

-

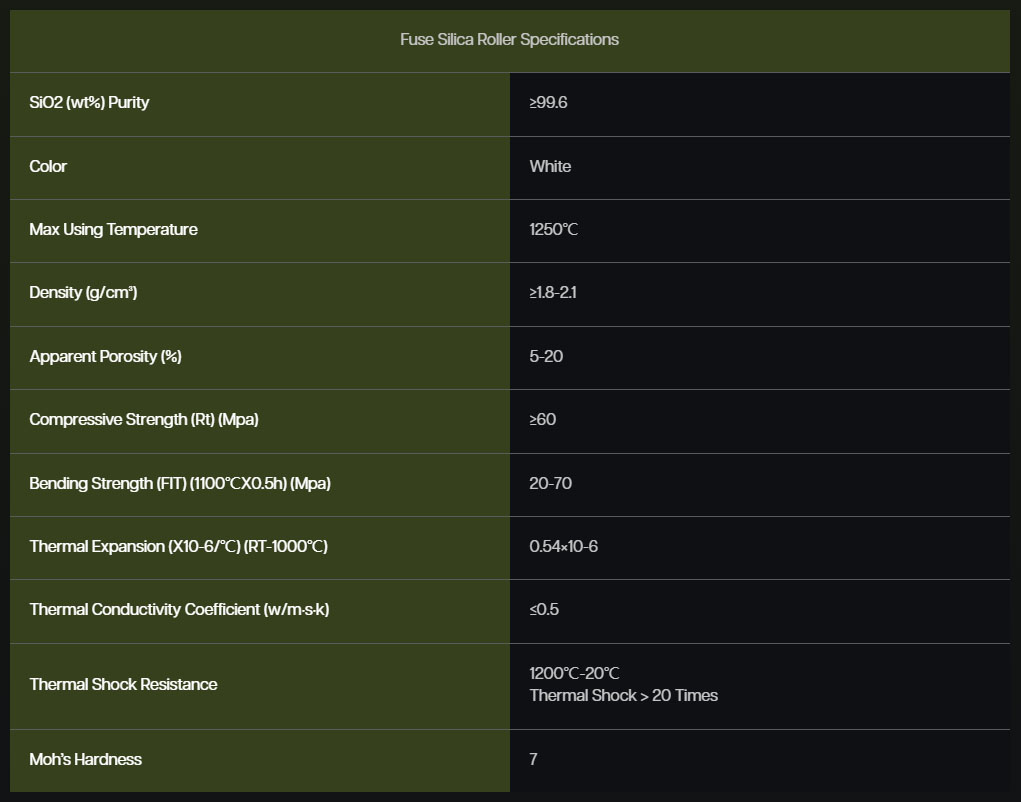

ዝርዝር መግለጫ

-

FQA

A Fused Silica Ceramic Roller is a specialized industrial component crafted from fused silica ceramic material, meticulously designed to withstand the rigorous demands of various industrial processes. These rollers are employed in a diverse array of industries, including glass manufacturing, steel production, ceramics, semiconductor fabrication, and chemical processing, where precision, አስተማማኝነት, and thermal stability are crucial.

Applications of Fused Silica Ceramic Roller

የመስታወት ማምረት: Used in glass tempering, annealing, and coating processes for precise control over glass movement and heating.

Steel Production: Employed in steel rolling mills for guiding and supporting steel strips during the rolling process, ensuring uniform thickness and quality.

Ceramics Industry: Utilized in ceramic production for shaping and forming ceramic products with high precision and accuracy.

Semiconductor Manufacturing: Applied in semiconductor fabrication for wafer handling and processing, ensuring contamination-free production environments.

Chemical Processing: Used in chemical reactors and vessels for stirring and mixing corrosive substances, providing reliable performance in harsh chemical environments.

Why Choose ካምሮልቸሮች የተቀላቀለ ሲሊካ ሴራሚክ ሮለር

የጥራት ማረጋገጫ: Manufactured to the highest quality standards, Fused Silica Ceramic Rollers undergo rigorous testing to ensure durability, አስተማማኝነት, and consistent performance.

የቴክኒክ ልምድ: Backed by expertise in materials science and engineering, we provides expert guidance and support to customers, assisting in selecting the right rollers for their specific applications.

Global Reputation: Trusted by industrial manufacturers worldwide, Kamroller has established a reputation for excellence, አስተማማኝነት, and customer satisfaction in providing Fused Silica Ceramic Rollers.

የእኛ የፋብሪካ ምስል:

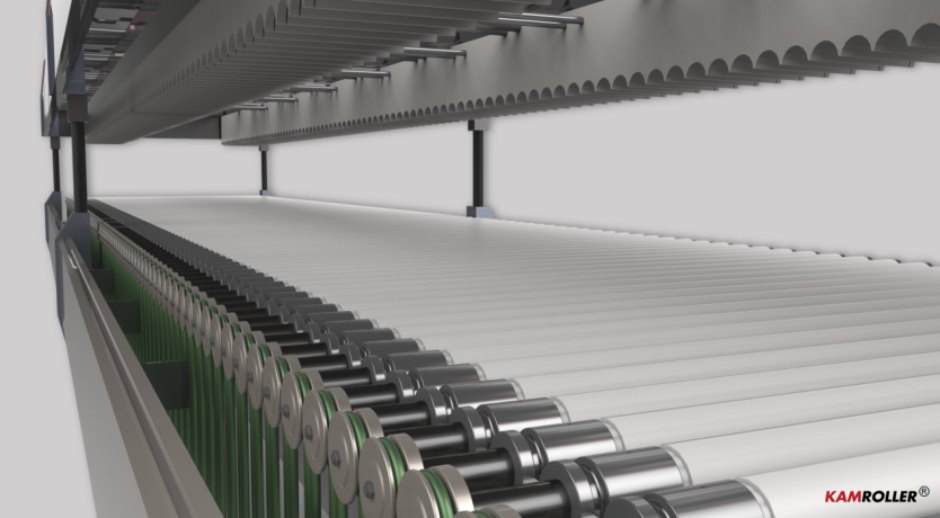

Kamrollers Rollers On the Glass Tempering Furnace:

የማሸጊያ ዝርዝር:

Kamrollers At The Exhibition:

Iso የምስክር ወረቀት:

Fused Silica Ceramic Roller ምንድን ነው??

A Fused Silica Ceramic Roller is a specialized industrial component made from fused silica ceramic material. It is designed to endure high temperatures and harsh conditions in various industrial processes, offering excellent thermal stability, precision, and reliability.

What Industries Use Fused Silica Ceramic Rollers?

These rollers are widely used across several industries, ጨምሮ: የመስታወት ማምረት: For handling glass sheets and preventing thermal shock. Steel Production: For transporting and processing steel at high temperatures. Ceramics: In the production and handling of ceramic products. Semiconductor Fabrication: For precise and clean operations. Chemical Processing: For handling corrosive materials and maintaining purity.

What are the Key Features of Fused Silica Ceramic Rollers?

ከፍተኛ የሙቀት መረጋጋት: Can withstand extreme temperatures without deforming or cracking. Precision: Engineered for high accuracy in industrial applications. Reliability: Durable and long-lasting under demanding conditions. የኬሚካል መቋቋም: Resistant to corrosion and chemical reactions.

Why Choose Fused Silica Ceramic Rollers?

Thermal Resistance: Ideal for processes involving high heat, reducing the risk of thermal shock. ጠንካራነት: Long service life even in harsh environments. ዝቅተኛ የሙቀት መጨናነቅ: Maintains dimensional stability under temperature changes. ለስላሳ ወለል: Minimizes damage to materials being processed.

How are Fused Silica Ceramic Rollers Manufactured?

These rollers are produced through a meticulous process involving the fusion of high-purity silica. The material is then shaped and finished to meet precise industrial specifications, ensuring optimal performance in high-temperature applications.

What Maintenance is Required for Fused Silica Ceramic Rollers?

Regular Inspections: Check for cracks, wear, and other signs of damage. ማጽዳት: Keep the rollers clean to prevent contamination and ensure smooth operation. Replacement: Timely replacement of worn or damaged rollers to maintain process efficiency.

What are Common Problems and Solutions?

Cracking: Ensure proper handling and avoid rapid temperature changes. Surface Wear: Regularly inspect and replace rollers to prevent material damage. Chemical Damage: Use appropriate rollers for specific chemical environments to prevent corrosion.

How to Select the Right Fused Silica Ceramic Roller?

Application Requirements: Consider the specific needs of your industrial process. Temperature Range: Ensure the roller can handle the maximum temperature of your application. Size and Shape: Choose the correct dimensions for compatibility with your equipment. Manufacturer Re